I have found over the years that Breeze Heating and Cooling Engineers are very consistent, and I have been very impressed with the response and professionalism from the whole crew from the boss down to the apprentice.

Julie Rodriguez

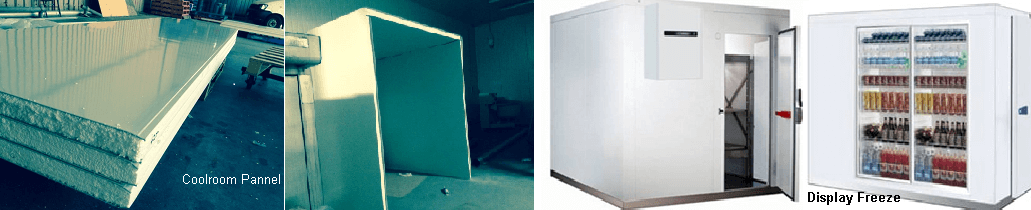

Breeze Heating and Cooling Engineers have designed cool rooms for the Food industry for more than 10 years. We have our own specialised team of four people who is a builder, forty years experienced refrigeration expert, refrigeration technician and a plumber. We have dealt with projects starting from 5k to 500k with guaranteed work and after sales service. Our team uses only high quality Australian Panels. PVC coated walls make these rooms ideal for storing fruit, vegetables, meat & dairy products. They can also be used for flowers, film, pharmaceutical & other temperature sensitive materials.

For Cool Rooms Installation , Hire and Repairs Become a Member in Melbourne Cool Room https://melbournecoolroom.com.au and Get 10% Discount

We use quality Insulated panels minimum 100mm thick, be of modular construction incorporating wall and ceiling panels and be of “woodless” type construction. Panels shall consist of insulation sandwiched between interior and exterior metal skin. Panel edges to have tongues and grooves that cam-lock together assuring an air tight vapour proof joint. All panel insulation we use shall be density polyurethane foam insulation expanded with “Ozone Safe” and Australian standard of AS 1530.3 equivalent to American ASTM E84.

We use upon request FM 4880 (Factory Mutual)Approval Global Standard for Class 1 Fire Rating of Insulated Panels, Interior Finish Materials or Coatings and Exteriors Wall Systems evaluates a panel’s ability to contribute to a fire in a variety of different ways, through a small corner test or larger scale corner test.

Door construction shall match the insulated panels. Each entrance to have a clear opening of 800 mm wide by 2000mm H. Doors shall be flush mounted, in-fitting and have a replaceable magnetic gasket on three sides and a neoprene adjustable gasket at the sill. Door hardware shall include three (3) heavy duty hinges, heavy door closer and a latch/release. In addition, each door shall be equipped with a 400 x400 heated viewing window.

If the Cool Rooms located on a concrete slab-on-grade will require a floor heating and insulating system underside floor panels. If insulated floor panel are to be provided, the floor panels shall be capable of withstanding loads. We might have to use checker plates for anti-slip mechanism and close openings between insulated panels and building walls. Seal all joints, openings, piping, electrical and ductwork penetrations (regardless of trade). Seal both sides of penetrations (if possible) and inside electrical conduit once wires have been pulled.

All electrical components utilized within each walk-in shall work performed provide the appropriate circuits to each condensing unit and a pull box located above each cold room. All interconnecting and control wiring to be by walk-in supplier. A fused disconnect is to be provided at each condensing Exposed conduit inside the cold room shall be kept to a very minimum.

Installation of all cold rooms in accordance with manufacturer’s written instructions and reviewed shop drawings and Install sheet metal closure trim that matches insulated panel finish between all building walls and insulated panels. Verify placement of all exposed piping and conduit with the Owner’s Representative prior to installation. Install interconnecting accessories in accordance with the manufacturer’s written recommendations and located for ease of servicing. Provide piping in accordance with good engineering practice. Suction line insulation shall be sized and installed to prevent condensation. We provide individual traps for condensate drains. Pre-test all equipment operation and performance of each walk-in, make all adjustments and repairs as required. H Clean all rooms inside and out, including the roof of each walk-in. Remove all debris and marks.

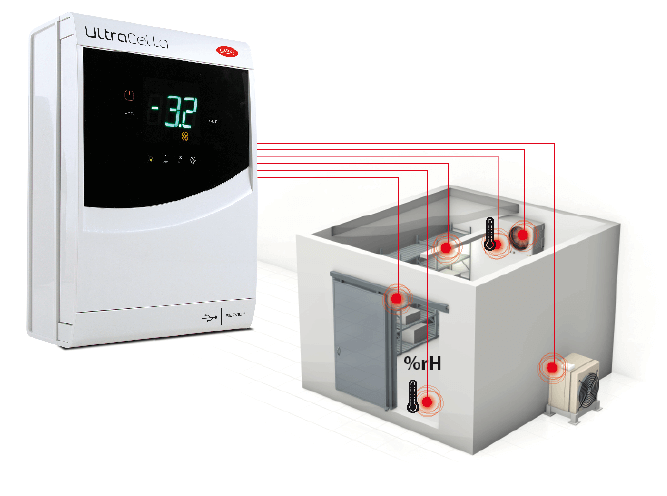

All our controls must have compressor control with pump down capability, controlling condenser fan, variable speed evaporator fan motor. Better sensing with up to 4 temperature probes, intelligent logic based on average measurement of two temperature sensors plus humidity sensor.

Our controller USB support and Configuration after commissioning you can save parameters on USB key for your next cold room also a HACCP standards means - temperature and alarm data logging, and user can save data easily to a USB key.

https://www.breezeweb.com.au/freezers-melbourne.html

https://www.breezeweb.com.au/refrigeration-repairs-melbourne.html

Same day service

Call 0433 321 727 or contact us by filling out the contact form.